Researchers at northwestern university and the university of Illinois at Chicago used 3d-printed super-elastic bone to regenerate skull defects in mice. These results may eventually lead to the development of a much needed, cost-effective craniofacial bone graft solution.

Although further experiments are needed, the researchers said, "our study highlights the potential translational potential of this new strategy in tissue engineering applications, particularly bone regeneration."

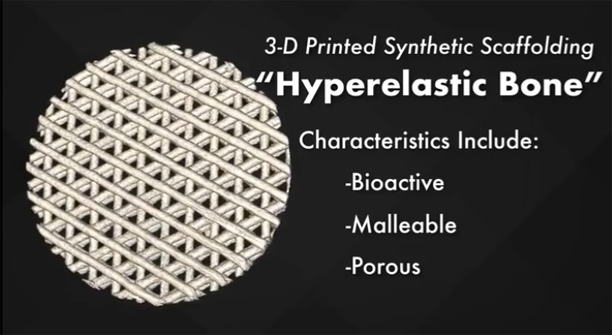

3D printed super elastic bone scaffold

3D printing for bone regeneration

Hyperelastic bone is made from hydroxyapatite, the main mineral in bone, and polyglycolic acid. As the name suggests, this mixture provides the material with high elasticity and biocompatibility, making it an excellent, potential natural bone substitute.

Especially in craniofacial reconstruction, the northwestern university /UIC team recognized that irregular defects could benefit from the plasticity and customization of 3D printed implants with high comfort. To investigate this question, in a recent study, the team used the material to create artificial scaffolds with complex grids, mimicking the structure of natural bones.

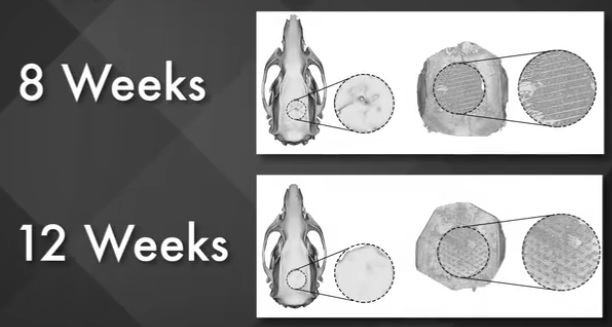

These stents were then implanted 8mm into the skull or skull defect of the rat to study its bone regeneration ability.

3D printed super-elastic bone scaffolds can promote the regeneration of rodent skull tissue in a few weeks

A plastic bone substitute

Microscopic examination showed that the effective rate of 3D printed super elastic bone scaffolds was 74% after 8 weeks and 65% after 12 weeks. During this time, the implant is gradually surrounded by fibrous tissue, and then by new bone cells, which eventually grow into new bone. Overall, 3d-printed implants produced 10 percent more bone volume than standard bone grafts.

The team concluded that an alternative to 3D printing could translate clinically to treating human skull defects. Studies have also shown that high-elastic bone stents are malleable enough to be pressed or cut during surgery.

The study's full results are published in the journal of plastic and reconstructive surgery. Yu hui huang, Adam yakus, sumanas Jordan, zari dumanian, kelly parker, pinh chao, praveen patel, and ramil shah are the authors of the book, 3d printed super elastic bone scaffolds accelerate bone regeneration for critical size skull defects